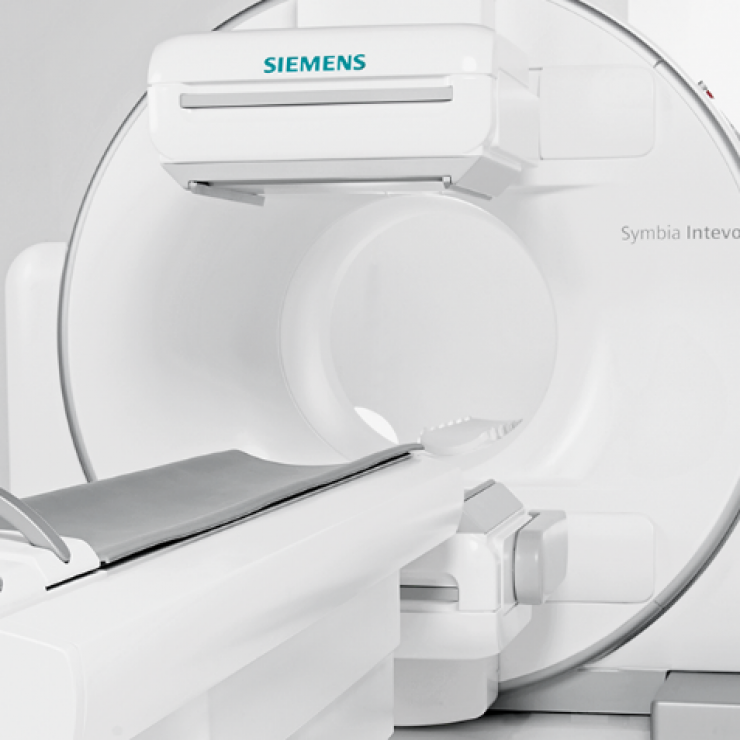

SOMATOM go.Sim

Simulation reinvented

SOMATOM go.Sim is a highly flexible, intuitive CT simulator. With fully integrated hardware and software tailored specifically to your requirements, it increases certainty and reduces the likelihood of errors. It also features advanced algorithms, AI-powered organ-at-risk (OAR) autocontouring, and excellent soft-tissue contrast potentially decreasing target margins. What’s more, it is designed to care for both patients and users – with a calming environment, a simple operating concept, and a single vendor service contract.

SOMATOM go.Sim can increase workforce productivity and optimize clinical operations. It helps you get the full picture faster so you can spend less time managing CT simulation and more time focusing on patients.

. Drive precision for contouring

Clinical Use

Reinventing CT simulation with SOMATOM go.Sim – a highly flexible, intuitive CT simulator that we designed in collaboration with over 300 RT specialists – radiation oncologists, medical physicists, dosimetrists, RTTs, and financial decision makers – to give us insights into your world. The result is a groundbreaking approach to CT simulation. It will give you everything you need to achieve the ultimate starting point for optimal RT planning, and will help you produce the most successful outcomes possible.

Be certain in simulation

60% of all RT incidents are caused by manual operation and data exchange4

. Successful CT simulation needs efficient and fail-safe workflows

. Current processes mean users have to switch between multiple software and hardware solutions

Lack of integration leads to errors and uncertainty in CT simulation.

Integration is a key factor to avoid potential error-prone CT simulation workflows

SOMATOM go.Sim comes with fully integrated hardware and software tailored specifically to your requirements. It offers unparalleled operational flexibility, and intuitive guidance.

This is a workflow that gives you certainty in simulation: It’s smooth, fast and is able to deliver the reproducible and user-independent results you need.

Be certain with guided CT simulation thanks to GO technologies

Be certain with a new patient-marking solution thanks to the mobile workflow

Be certain that the lasers are always spot on thanks to Direct Laser QA

Be certain with guided CT simulation thanks to GO technologies

Be certain with a new patient-marking solution thanks to the mobile workflow

Be certain that the lasers are always spot on thanks to Direct Laser QA

Be certain with guided CT simulation thanks to GO technologies

Your benefits

. Seamless and less error-prone processes thanks to the new mobile workflow

. Streamlined laser QA thanks to fully integrated Direct Laser

. Intuitive and guided CT simulation thanks to GO technologies

“The interface of the system is very intuitive and easy to operate. The mobile tablet maximizes the time with the patient and helps us to provide the best care at the starting point of treatment.9″Juliane Krestine Fuglsang

Radiographer, Aarhus University Hospital, Aarhus, Denmark

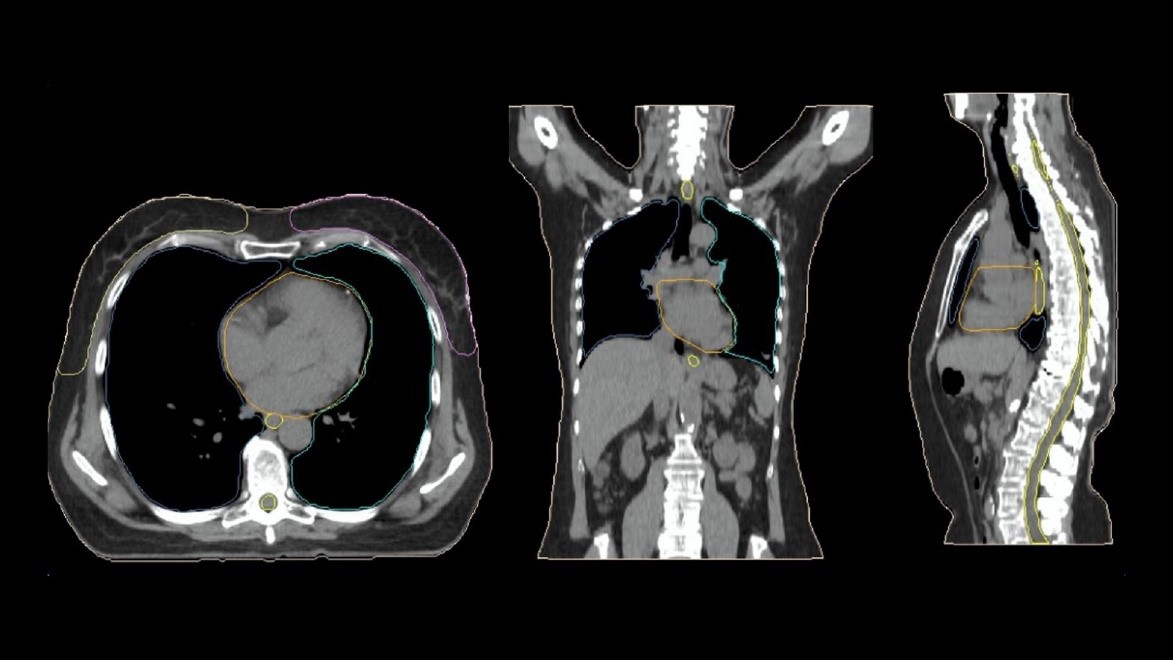

Drive precision for contouring

Courtesy of Hospital Del Mar, Spain.

Poor scope for accurate contouring hinders confident treatment planning

. Modern treatment techniques require precise planning

. CT simulation must consistently deliver high-quality patient modeling for the tumor and surrounding organs

. Yet the data provided for contouring are often not precise enough

Contouring is a major source of variability in RT planning6

Drive precision for OAR contouring

Courtesy of University Hospital Aarhus, Aarhus, Denmark

Radiation oncology professionals have to spend time manually correcting poor autocontouring

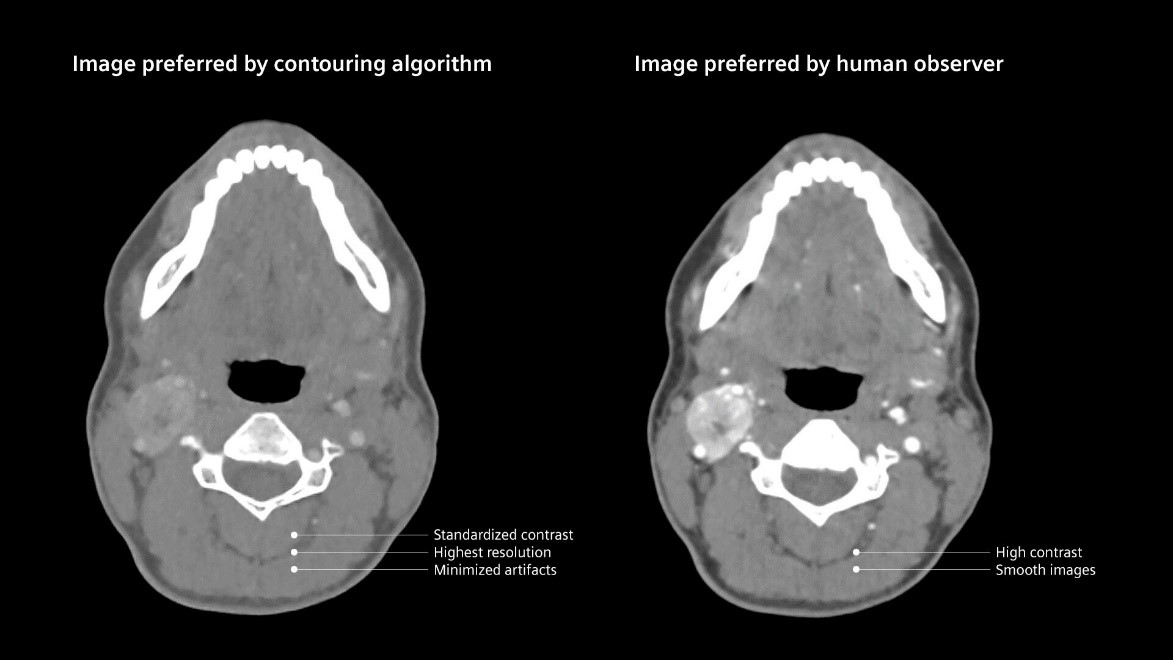

. The quality of autocontouring depends on the quality of the CT images

. Suboptimal image quality (caused by metal artifacts, poor soft-tissue contrast, etc.) leads to suboptimal autocontouring7,8

In the worst-case scenario, radiation oncology professionals have to redo the OAR contouring entirely by hand.

Courtesy of Radiology Department, Hospital Particular de

Viana do Castelo, Viana do Castelo, Portugal.

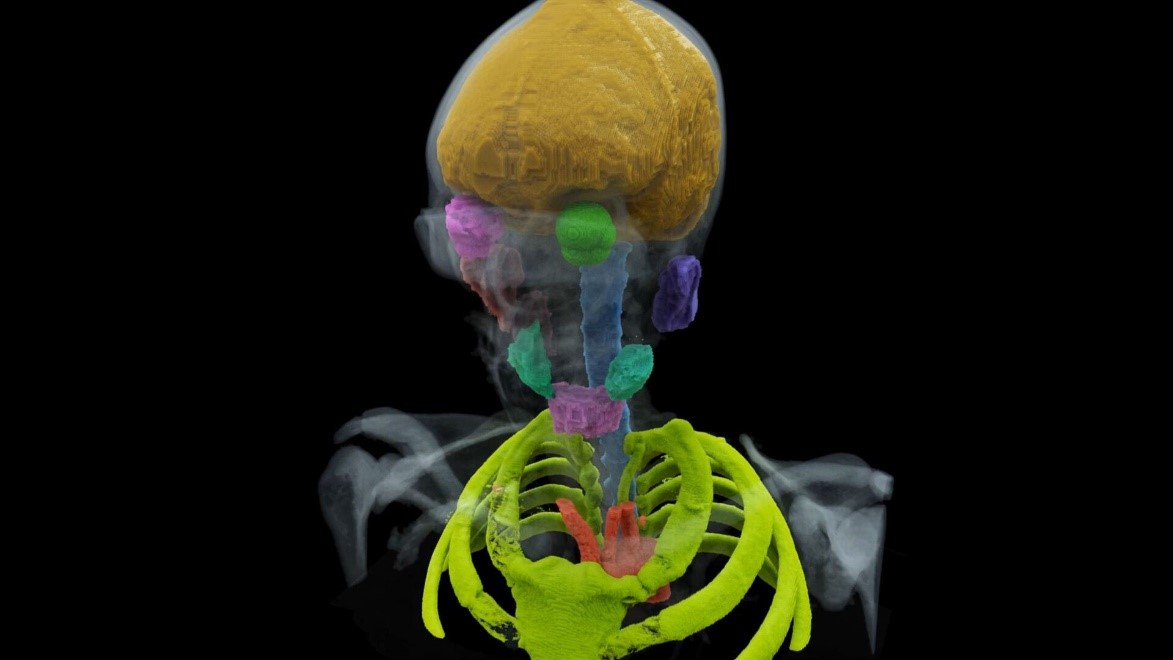

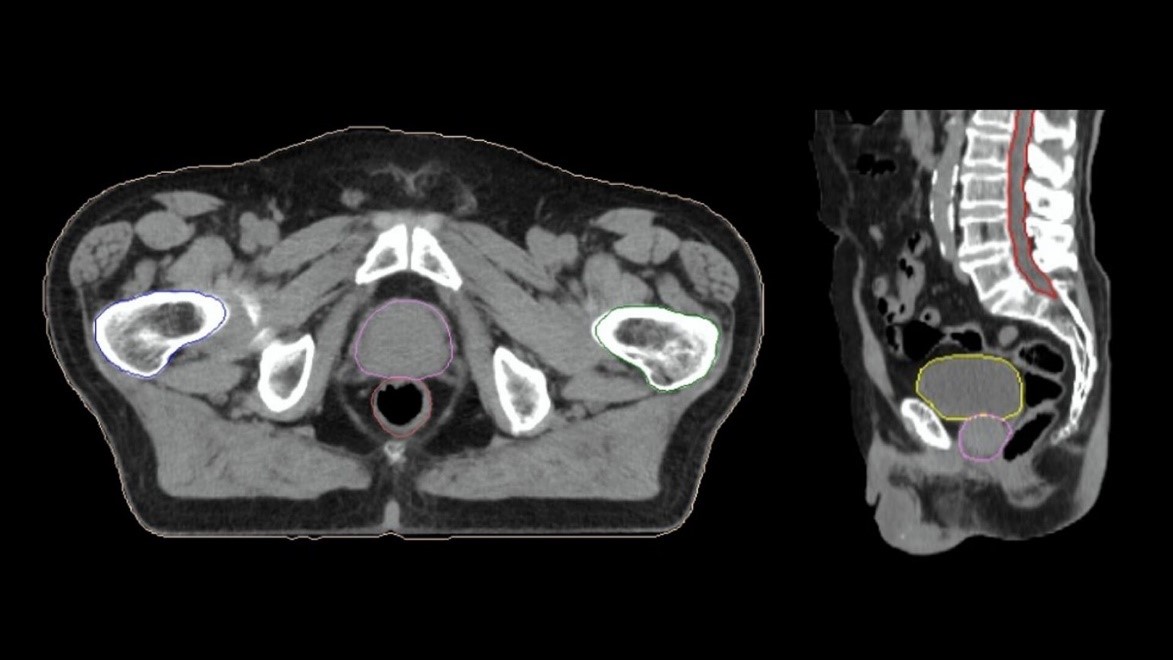

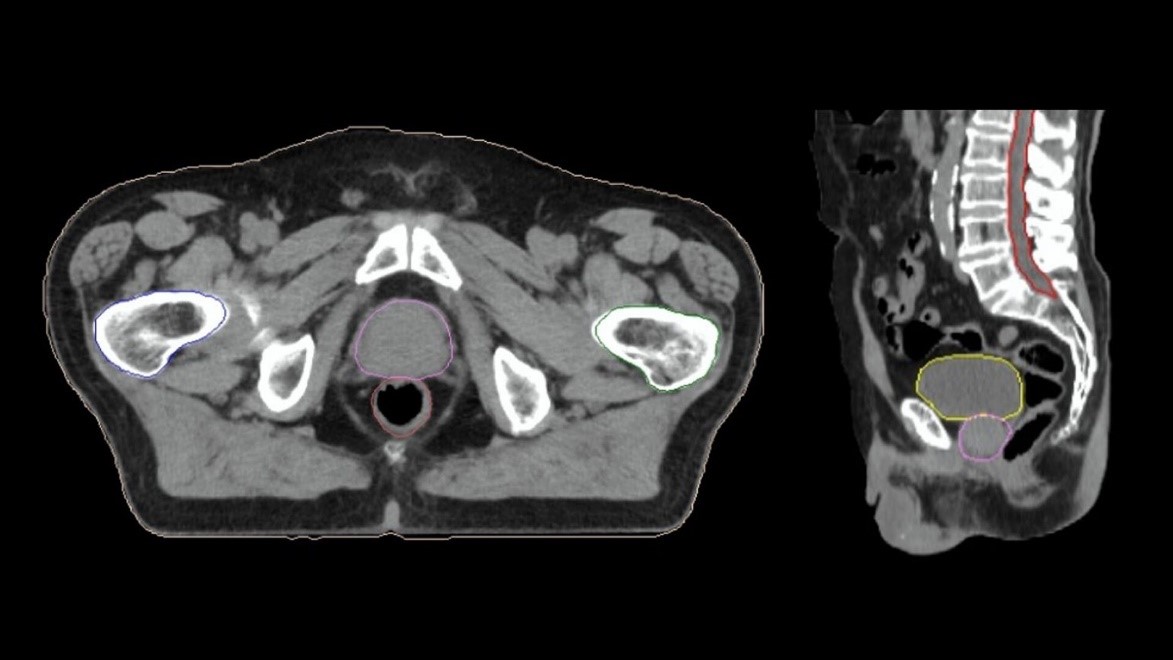

Consistent OAR contours generated directly by the CT simulator with DirectORGANS3

SOMATOM go.Sim features DirectORGANS3 (Optimized Reconstruction based contours trained by Generative Adversarial Networks) an AI-powered OAR contouring that automates and standardizes key steps in the CT simulation pathway. The high-quality information arrives directly as TPS-ready data.

Courtesy of Radiology Department, Hospital Particular de Viana do Castelo, Viana do Castelo, Portugal.

An autocontouring algorithm needs a specific type of image to perform contouring

DirectORGANS3 optimizes the images specifically for the algorithm.

This paves the way for consistent OAR contouring powered by AI.

DirectORGANS3 is a revolutionary, AI-based OAR contouring solution. The result reduces unwarranted variations with high-quality contours that approach the level of consensus-based contours. It leverages optimized and standardized reconstruction parameters to deliver input to the deep learning based contouring solution.

Your benefits

. OAR contouring directly in the system, no need for manual interaction

. Optimized images designed for the deep-learning algorithm

. High-quality contours that approach the level of consensus-based contours

Courtesy of Leopoldina Krankenhaus, Schweinfurt, Germany

Courtesy of Leopoldina Krankenhaus, Schweinfurt, Germany

Courtesy of Leopoldina Krankenhaus, Schweinfurt, Germany

Courtesy of Leopoldina Krankenhaus, Schweinfurt, Germany

Courtesy of Leopoldina Krankenhaus, Schweinfurt, Germany

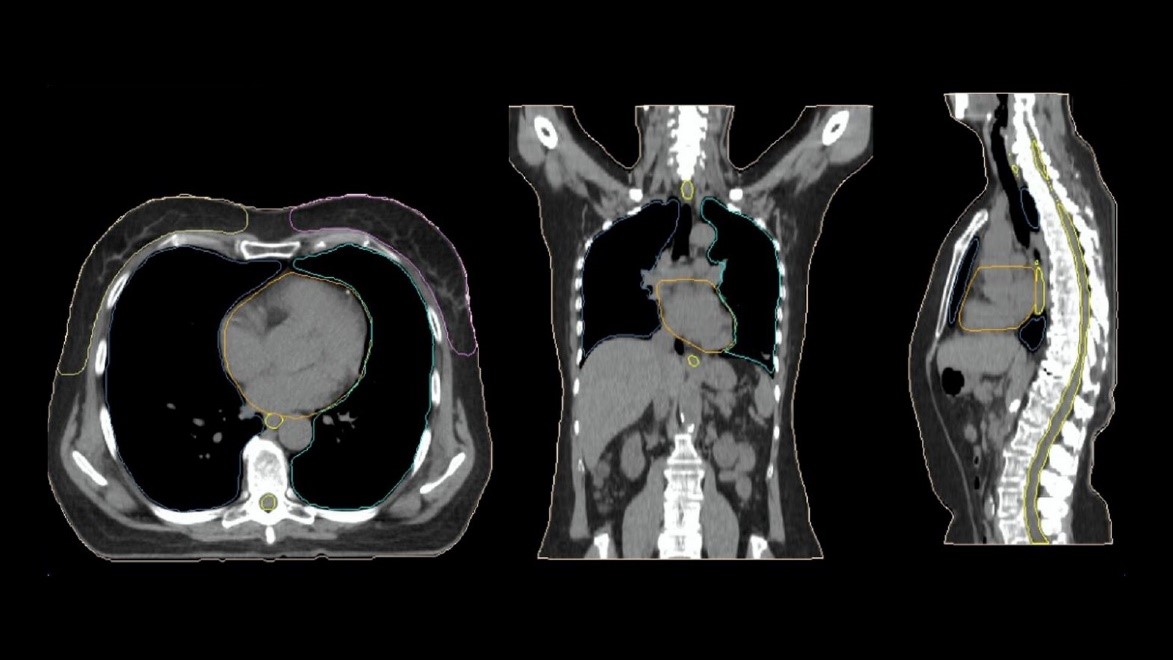

Drive precision in target contouring

A powerful combination of three innovative solutions delivers confident tumor visualization, precise target contours, and a straightforward 4D workflow: iMAR3 reduces metal artifacts, DirectDensity2,3 unlocks optimal kV settings with a single calibration curve, and Respiratory Motion Management3 optimizes scan parameters based on the patient’s breathing.

Your benefits

. Confident tumor visualization thanks to automated metal artifact reduction with iMAR3

. Precise target contours with optimum kV imaging and a single calibration curve thank to DirectDensity2,3

. Straightforward 4D workflow thanks to comprehensive respiratory motion management3

DirectDensity2,3 unlocks a wider range of tube voltages in CT scanners for better imaging quality while maintaining similar dosimetric accuracy.9Tianyu Zhao, PhD

Assistant Professor in Radiation Oncology, Washington University School of Medicine, Department of Radiation Oncology, St. Louis, MO, USA

Care for patients and users

Anxious patients and time-pressured operators can lead to suboptimal CT simulation

. Current CT simulation can create anxiety for patients and pressure for operators

. Operators have to spend a lot of time outside the examination room

. Installing and maintaining a multi-vendor system is complex and time-consuming

49% of patients feel distressed and anxious.10

If operators are under less time pressure, they can devote more time to caring for patients and generating high-quality results. If patients feel at ease, their CT simulation will be more successful.

Improve the patient experience with a patient centric design, co-created with RT professionals

. Total freedom over how and where you set up the simulation, and more time with your patient thanks to the mobile workflow

. A calming environment for the patient thanks to the ring mood lighting

. More comfort for patients thanks to the large 85-cm bore

Benefit from a shorter learning curve and easier vendor management with an all-in-one solution

. One revolutionary user interface

. One call center

. One maintenance appointment

. One service contract

. One training session

SOMATOM go.Sim creates a comfortable and calming environment for patients, and enables staff to spend more time at their side.

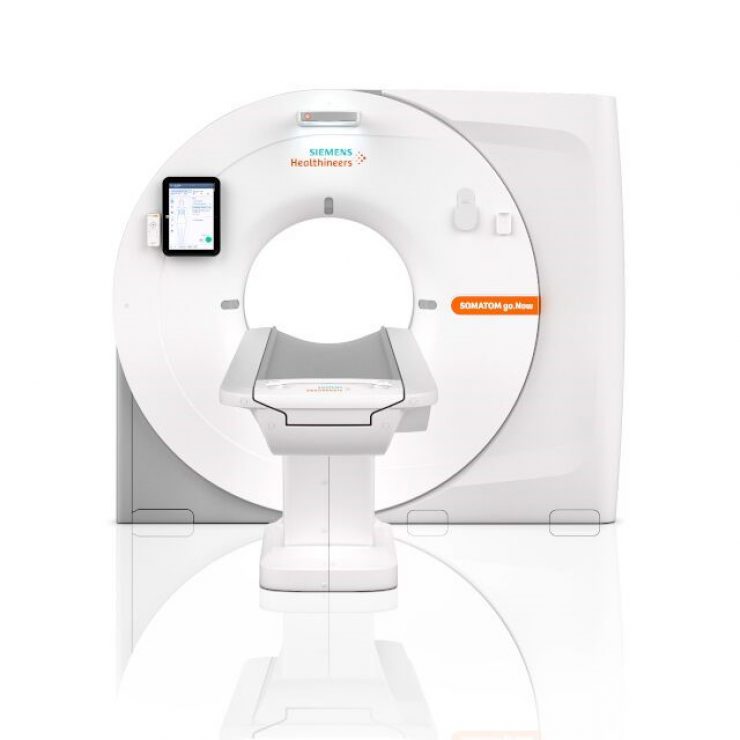

Technical Specifications

|

Bore size |

85 cm |

|

Scan Field-of-View (sFoV) |

60 cm |

|

Acquired slices/reconstruction slices |

32/64 |

|

Z-axis coverage |

1.92 cm |

|

Rotation time |

0.353, 0.5, 1.0 s |

|

max. table load |

227/3073 kg (TG-66 compliant tables) |

|

System footprint |

4 m2/43 ft2 (surface area covered by gantry and moving table top) |

|

Min. room requirement |

17.3 m2/186.2 ft2 |

More Information

Downloads

. SOMATOM go.SIM brochure 3 MB

. DirectOrgans Whitepaper 6 MB